What is Spot UV? A Guide to This High-Impact Print Finishing Technique

If you're looking to elevate the look and feel of your printed materials, Spot UV is one of the most effective and visually striking finishing techniques available. Commonly used on business cards, brochures, packaging, and invitations, Spot UV adds a touch of shine that highlights key elements and gives print products a premium, professional appearance.

In this guide, we’ll explain what Spot UV is, how it works, and why it’s worth considering for your next print job.

What Is Spot UV?

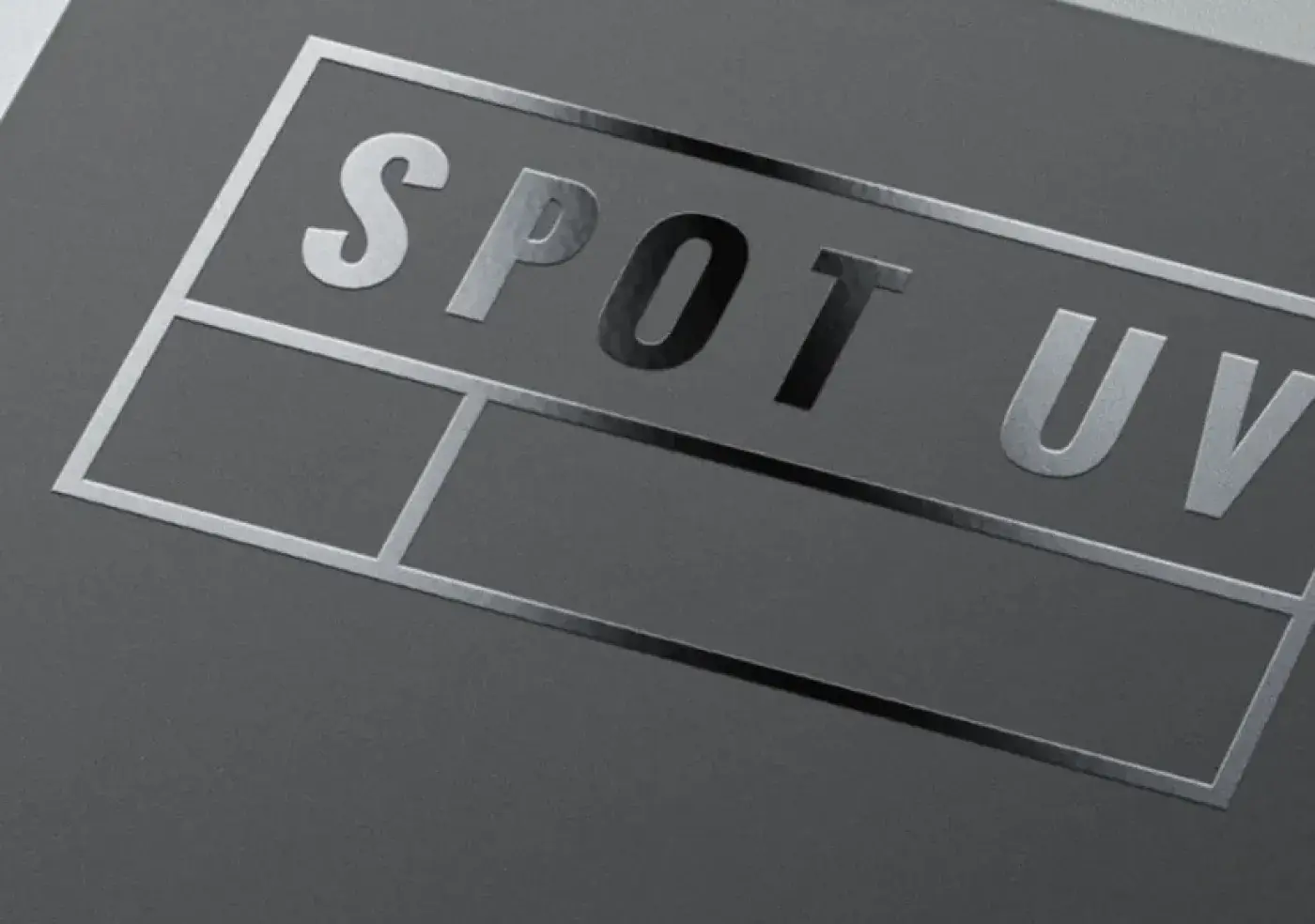

Spot UV (short for "Spot Ultraviolet") is a glossy coating applied to specific areas of a printed sheet such as a logo, image, or text to create contrast, texture, and shine. It’s called “spot” UV because it’s not applied over the entire sheet (like flood UV), but only to targeted spots of your design.

This technique is especially popular for:

-

Drawing attention to important design elements

-

Enhancing brand impact

-

Creating a tactile and visual experience

When applied over a matte or uncoated background, Spot UV stands out even more, offering a dynamic contrast between shine and flatness.

How Does Spot UV Work?

The process uses a clear, liquid varnish that is applied to the desired areas and then instantly cured using ultraviolet (UV) light. Modern digital Spot UV equipment—like the Duplo DuSense DDC-810 Pro or DDC-8000—makes this process incredibly precise and efficient.

Here’s a simplified breakdown of the workflow:

1. Design the Base and Spot Layers

You’ll first create your main design (usually in CMYK) and a second file that indicates where the Spot UV should be applied. The Spot UV layer is typically set in 100% black where the coating will go and left white or blank where it won’t.

2. Add Registration and Imposition Marks

To ensure perfect alignment between the printed sheet and the Spot UV layer, registration marks are added during the file prep process.

3. Print the CMYK File

Your base design is printed using a digital press. Afterward, the sheets are loaded into a Spot UV coater.

4. Apply the Spot UV Coating

The coater reads the registration marks and applies the glossy varnish to only the designated areas. UV light instantly cures the varnish, making the sheets ready for handling, trimming, or additional finishing.

This process is quick, clean, and does not require screens or dies, which makes it highly suitable for short runs and custom jobs.

Why Choose Spot UV?

Spot UV isn't just about aesthetics, it brings strategic value to your printed materials. Here’s why it’s a go-to choice for marketing professionals and designers:

Increases Visual Impact

By catching the light and contrasting with matte or uncoated areas, Spot UV naturally draws the eye to key parts of your design making your brand or message more memorable.

Adds a Premium Look Without a Premium Price

Unlike traditional foil stamping or embossing, Spot UV gives your materials a high-end look without costly setup fees. That’s especially useful for small businesses and local organizations that want great design without going over budget.

Elevates Customer Perception

Whether you're handing out business cards or selling luxury packaging, Spot UV gives your products a professional and refined feel, subtly communicating that you care about details and quality.

Flexible for Many Applications

Spot UV works well across a wide variety of printed products:

-

Business cards

-

Brochures and flyers

-

Event invitations

-

Book covers

-

Product packaging

-

Presentation folders

-

Direct mail pieces

Is Spot UV Right for Your Project?

If you’re designing materials where first impressions matter, Spot UV is a smart finishing touch. It’s an easy way to enhance perceived value, highlight your brand, and improve reader engagement—without complicating your production workflow.

At American Business Machines, we help print shops and in-house marketing departments unlock the full potential of digital finishing. Our advanced print finishing equipment, including the Duplo DDC-810 Raised Spot UV Coater, makes it easy to offer stunning, high-margin print enhancements in-house.

Whether you’re a small business owner, a commercial printer, or part of an in-plant operation, our team can help you choose the right equipment to match your needs and grow your capabilities.

If you're ready to stand out with texture, shine, and impact, contact ABM to learn more about the Duplo DDC series or to schedule a demo. We'll help you find the right solution to meet your quality goals and expand your offerings.

.png?width=500&height=500&name=Untitled%20design%20(16).png)